Ultra-high precision at the world’s highest level, realized by a newly developed drive and guide systemPatent pending

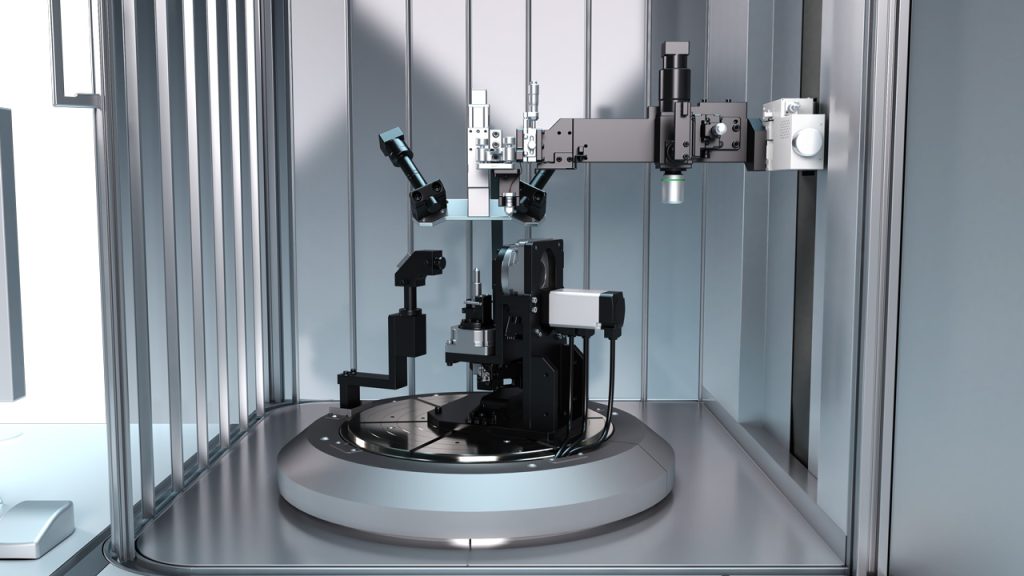

RONDCOM CREST is equipped with a newly-developed mechanism that consolidates all the tradition and technology of ACCRETECH on the column Z axis and the drive unit R axis. The drive system adopts a new method that combines the non-contact and low vibration linear motor drive technology that has earned a strong reputation among customers over the years in our surface roughness and contour measuring machines with a newly developed original Alignment mechanism. In addition, the guide system inherits the non-contact support technology using air bearings cultivated for years in CMMs then applied to the RONDCOM 60 series, in a newly developed mechanism that upgrades the air bearings to meet the low vibration specifications dedicated to RONDCOM CREST. Combining these drive and guide methods significantly improve rotation accuracy, alignment accuracy and straightness of each axis, realizing world-class ultra-high accuracy suited for a reference machine. In addition, since both the drive and guide systems have a non-contact structure, there is no wear on the guide section, maintaining stable high accuracy over a long period of time. ACCRETECH presents RONDCOM CREST FiANA, a new measuring instrument created by equipping an ultra-thin probe on RONDCOM CREST, which boasts one of the highest accuracies in the world. FiANA enables non-contact measurement inside ultra-small holes down to 0.14 mm.

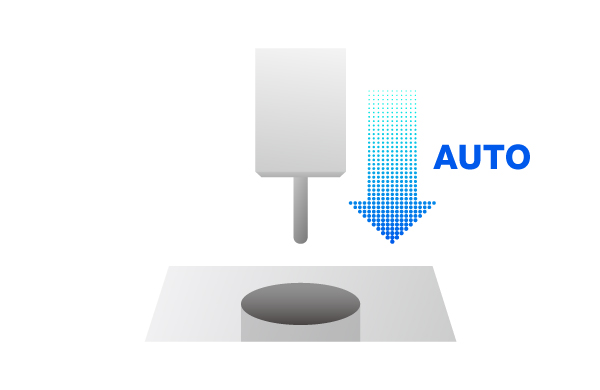

Equipped with an automatic probe insertion system

RONDCOM CREST is equipped with an automatic probe insertion system (patent pending), making measurement easy for anyone.

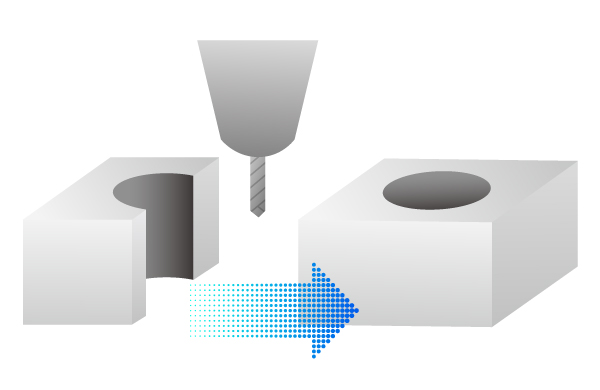

No need for cross-cuts

There is no need to prepare cross-cuts. Measurement can be started right away.

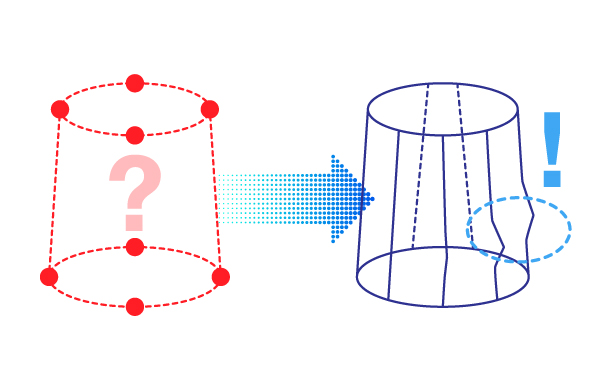

bundant information with scanning measurement

A switch from Single point measurement to scanning measurement offers an abundance of information from point clouds, enabling detailed analysis.